CIJ vs. Laser: Which coding technology is right for your packaging line?

Videojet Knowledge Hub Team

CIJ printing for packaging lines, laser marking, coding technology comparison

Which coding technology is right for your packaging line?

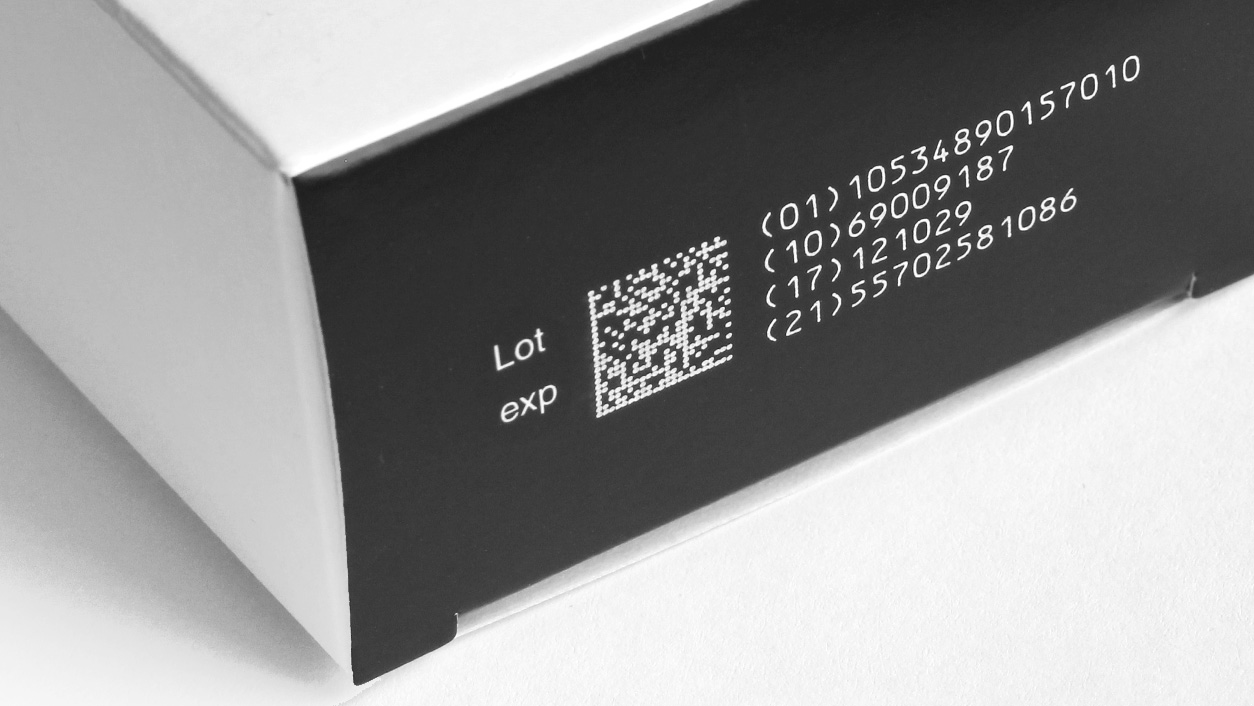

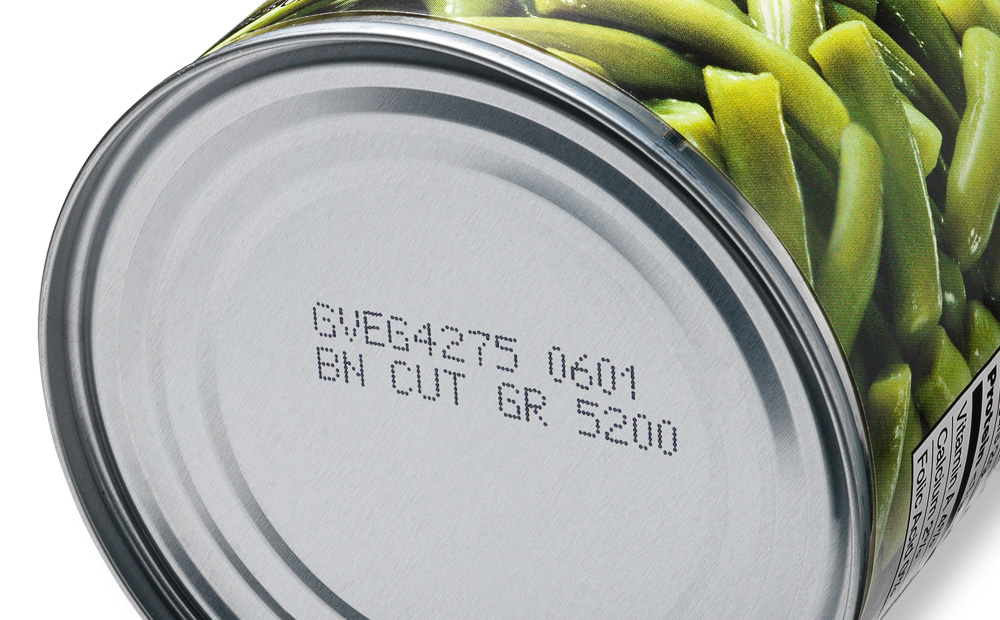

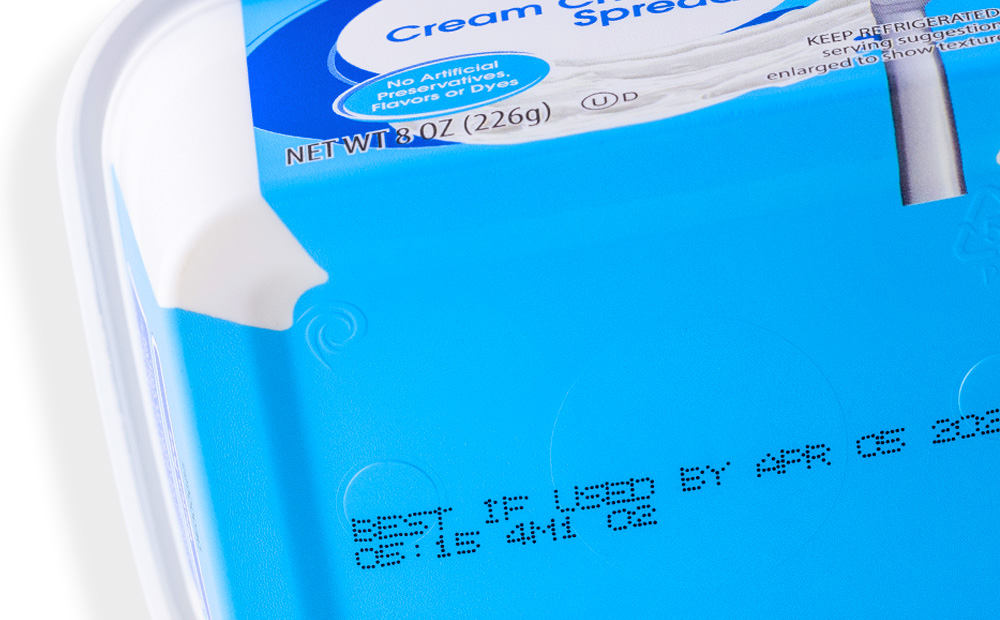

When it comes to coding and marking on your packaging line, one choice can make all the difference: continuous inkjet (CIJ) printing or laser marking? These two technologies are widely used to add essential information like barcodes, batch numbers, and date codes directly to products.

The right decision depends on factors like material compatibility, durability, cost, and sustainability goals. Selecting the ideal solution ensures efficiency, protects brand integrity, and can deliver long-term operational savings. So, how do you determine which technology is best suited for your production needs? Let’s explore the key differences, benefits, and considerations to help you make an informed choice.

What is the difference between CIJ printing and laser marking?

CIJ uses ink droplets to print variable data on products, while laser marking uses light beams to create permanent marks. The right choice depends on your production needs, materials, and long-term goals.

Why does the choice of coding technology matter?

Your coding and marking technology is more than just a tool, it’s a critical factor in helping to ensure product compliance, traceability, and branding. Both CIJ and laser marking are highly effective non-contact methods, but they differ in cost, material compatibility, and long-term performance.

How does laser marking work and what are its benefits?

How does laser marking work and what are its benefits?

Laser marking uses focused beams of light to alter the surface of a material, creating high-quality, permanent marks that are resistant to wear and tear. It is best suited for industries that require durable, legible codes for compliance, branding, and traceability.

Which laser type should you choose: CO₂, fiber, or UV?

Laser marking systems for package coding are available in three main types, each designed to perform on specific materials:

| Laser type | Best suited for | Sample applications |

|---|---|---|

| CO₂ lasers | • Non-metallic and organic materials, such as paper, cardboard, glass, wood, and certain plastics. |  |

| • Frequently used in the food and beverage industry to mark codes on packaging like paperboard cartons, as well as PET and glass bottles. |  | |

| Fiber lasers | • Marking on food and beverage packaging, including cans, flexible films, foils, and labels. |  |

| • Frequently used in the automotive, aerospace, and electronics industries where permanent, high-contrast marks on durable materials are essential: high-density plastic and metal, including stainless steel, aluminum, brass; automotive parts; and electronic components. |  | |

| UV lasers | • Heat-sensitive materials, such as medical-grade plastics, soft polymers, and certain types of glass. |  |

| • Ideal for marking on films, foils and labels, and white HDPE containers. |  | |

| • Frequently used in the pharmaceutical and healthcare industries for precise coding of medical devices and delicate materials like syringes and blister packs. |

- CO₂ lasers: Best suited for paper, cardboard, glass, and certain plastics.

- Fiber lasers: Ideal for metals and hard plastics.

- UV lasers: Perfect for heat-sensitive materials like medical-grade plastics.

What is continuous inkjet (CIJ) printing and what are its benefits?

What is continuous inkjet (CIJ) printing and what are its benefits?

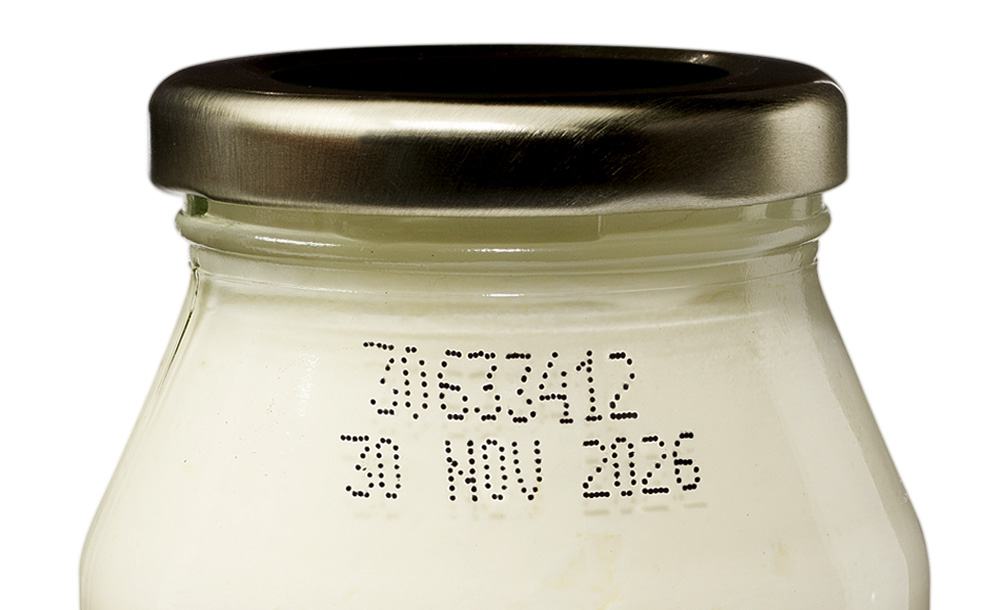

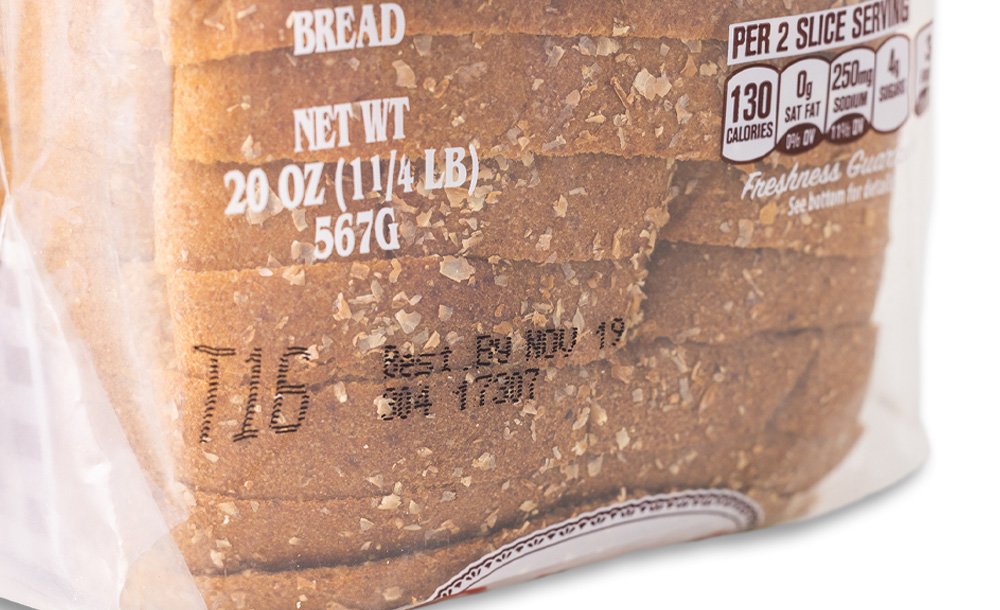

Continuous inkjet (CIJ) printing is a proven technology that excels in all production environments, from low to high speeds. It uses a continuous stream of ink droplets to create variable data, such as dates, lot codes, and barcodes, directly onto products or packaging.

What are the benefits of continuous inkjet (CIJ)?

- Material compatibility: Prints on a wide range of substrates, including plastic, metal, glass, paper, cardboard, wood, and more.

- Versatile application: Suitable for flat, curved, and irregularly shaped surfaces, making it highly adaptable for diverse product types.

- High-speed performance: Capable of producing up to five lines of text at high production speeds.

- Proven reliability: Widely used in industries such as food and beverage, pharmaceuticals, and consumer goods to print essential product information.

How do CIJ and laser compare across key performance factors?

| Factor | Laser marking | CIJ printing |

|---|---|---|

| Durability | Produces permanent, tamper-proof marks resistant to fading, smudging, or removal. Ideal for traceability. | High-adhesion inks withstand scuffs, scratches, sun, and moisture. Permanent marks possible with heat curing, overcoat varnishing, and UV curing. |

| Material compatibility | Offers three laser types for different surfaces: • CO₂ lasers: Paper, glass, wood, organic materials • Fiber lasers: Metals, hard plastics • UV lasers: Heat-sensitive materials, flexible films, glass | Prints on virtually any substrate, including flexible films, glass, metal, plastics, and curved surfaces. |

| Cost and maintenance | Higher upfront investment but minimal maintenance; no consumables; fewer interruptions lead to long-term savings. | Lower initial cost but requires ongoing ink replenishment, periodic servicing, and regular maintenance. |

| Print quality | Crisp, high-resolution, high-contrast marks including 1D/2D codes, logos, and multi-line text. | Reliable dot-matrix codes; micro-sized high-resolution codes possible; inks available in various colors and special properties (color-changing, invisible/fluorescing). |

| Speed and integration | Excels in compact spaces; ultra-fast coding for high-volume production lines. | Ideal for ultra-high-speed applications (beverages, pharma, packaged goods); flexible printhead configurations for top, side, or bottom printing. |

| Sustainability | No consumables like ink or ribbons; can help reduce waste and environmental impact. | Modern CIJ printers use ink efficiently to minimize waste during coding. |

By carefully evaluating these factors, businesses can make an informed decision about which marking technology best suits their operational requirements and long-term objectives.

Which technology is the best fit for your production line?

The decision between CIJ and laser marking comes down to your specific production needs:

Choose laser marking if you require durable, high-quality marks that prioritize traceability, compliance, and long-term cost savings.

Choose laser marking if you require durable, high-quality marks that prioritize traceability, compliance, and long-term cost savings.

Choose CIJ printing for a cost-effective, versatile solution that works across a variety of substrates, whether you’re running low, mid-range, or high-speed production lines.

Choose CIJ printing for a cost-effective, versatile solution that works across a variety of substrates, whether you’re running low, mid-range, or high-speed production lines.

Where can you get expert help to decide?

At Videojet, we recognize that no two production lines are the same. Whether you need versatile coding for a variety of substrates or permanent marking for traceability and compliance, our team of experts is here to assist. From evaluating your production line to providing sample testing, we’ll help you find the coding solution that fits your unique needs.

Contact a Videojet product expert today for a free consultation or sample testing. Let us help you find the perfect coding and marking solution to keep your production line moving.