Find out more about our technology

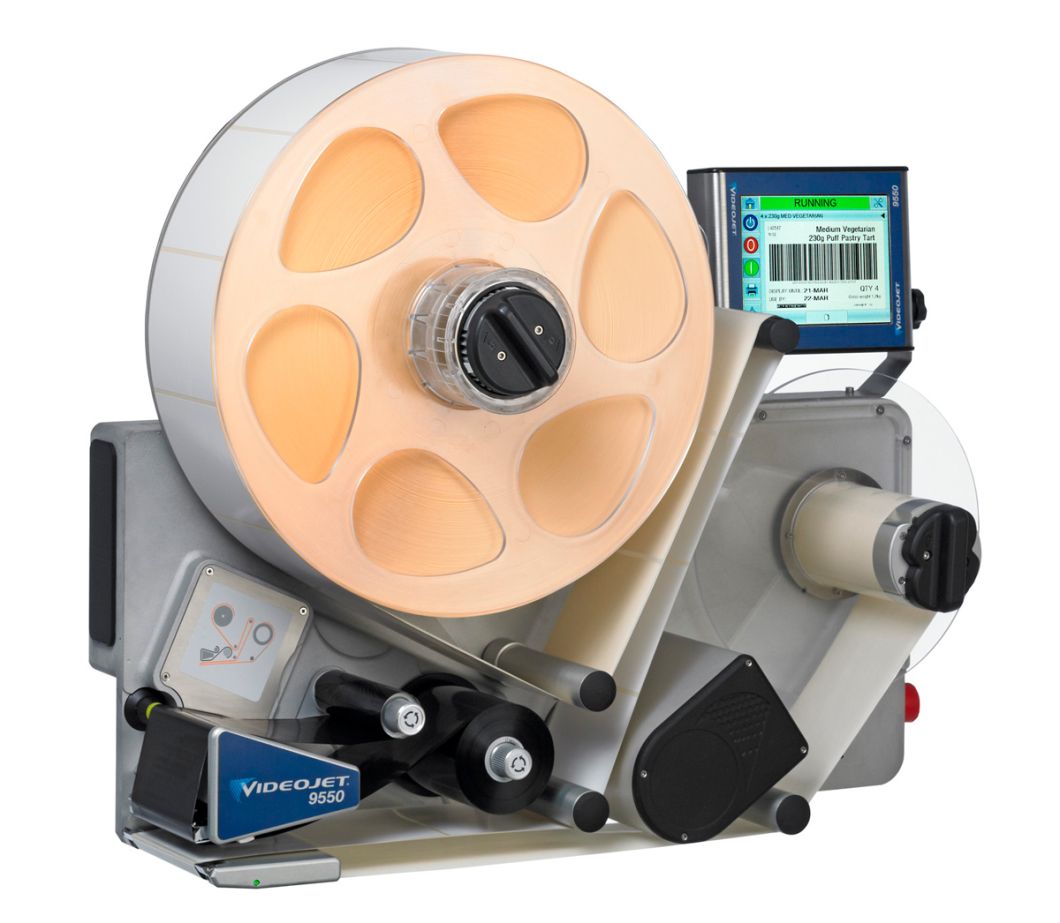

Videojet 9550 (LPA)

The 9550 with Intelligent MotionTM technology is a smarter print and apply labeller that targets zero unscheduled downtime and reduces costs and errors in case coding operations. Automatic, precise control of the entire system, together with Direct Apply label placement, provides the most efficient and reliable labelling machine.

Videojet 2300 (LCM)

The Videojet 2300 Series is a family of three high-resolution, large character inkjet printers that provide class-leading, consistent print quality on porous and secondary packaging materials. These printing systems are designed and manufactured to reliably print accurate, high-quality, real time alphanumeric codes, bar codes and graphics. Available in a range of printhead heights to best suit your printing needs, the Videojet 2300 Series can replaces pre-printed boxes and labels with a highly flexible, cost effective printing solution.

The evolution of print and apply labelling for homecare & personal care products

Counterfeiting is a growing concern for manufacturers of homecare and personal care products. This concern is leading to the adaptation of comprehensive coding solutions for product packaging. For example, for retail, some manufacturers are applying barcode labels onto all of their homecare and personal care goods as well as their respective outer case packaging.

Historically, when it came to label application on outer cases, manufacturers would either pre-print labels offline from a print room and apply them by hand or use a traditional labelling machine. To reduce the manual labour required in hand labelling, some started using custom-built applicator systems – taking labels from a desktop printer and automatically applying them to cartons.

The evolution from manual to automated application of labels resulted in the creation of complex pieces of machinery. They incorporated the actual labelling machine with an unwind and rewind assembly, a separate print engine inserted into the base of the system and a label applicator. With this, the first Print and Apply Labelling (LPA) system was born. While an improvement, LPA systems were not without challenges as the technology necessitated constant manual adjustments. Frequent adjustments were required due to parts breaking down and as a result of label misalignment or labels getting stuck in the machinery. This ultimately caused a high level of unscheduled downtime, frustration among operators, loss of production time, label waste and increased cost.

More than two decades have passed since the invention of the first LPA machine, and more than ever, production managers are facing pressure to reduce operational costs and improve productivity and efficiency. And now, not only do manufacturers have to juggle the requirements of their supply chain partners, but they must comply with increasing local and international coding, labelling, and product safety standards and regulations. In the outer casing industry for example, legible information and unique codes have to be printed on every package for traceability purposes.

The foundations of LPA design haven’t changed since their inception; however recent innovations mean that coding machines can now do much more than simply print lot numbers. Advanced LPA software enables manufacturers to track products through their distribution chain – within their factories and all the way to the retailer. It does this by recording the lot numbers of each product as it passes through each assigned checkpoint on the production line. This data collection helps to confirm code quality as well as help in the fight against counterfeit products, ultimately helping to protect the brand.

Aside from achieving seamless traceability, homecare and personal care manufacturers are also seeking out printing technologies that facilitate easy product changeovers. This simplicity helps to minimise production downtime and addresses manufacturers’ requirements for production line flexibility. Manufacturers running single lines for multiple and short product runs of different products (e.g. limited edition and seasonal collections) find easy-to-use and flexible coding systems highly desirable. This functionality helps optimise productivity, allowing manufacturers to better meet fluctuating market demand without having to construct costly additional production lines.

With so much pressure to maximise productivity, reduce operational costs and uphold brand integrity, pressure on homecare and personal care manufacturers will likely only intensify. In the next article, the specific needs of these manufacturers are explored.