Sascha Ammesdörfer,

Videojet Director – Product Marketing & CI

27 July 2025

On a bustling production floor, a line comes to a sudden halt. A technician struggles to diagnose the issue, but a system’s outdated interface offers little insight. Meanwhile, supervisors wait anxiously for updates, and every passing minute reduces productivity. This scenario is all too familiar in today’s manufacturing landscape, where the lack of real-time visibility and fragmented system integration can lead to costly downtime and operational inefficiencies. This kind of inefficiency underscores the need for smarter, more connected solutions that can keep operations running smoothly – even in the face of unexpected challenges.

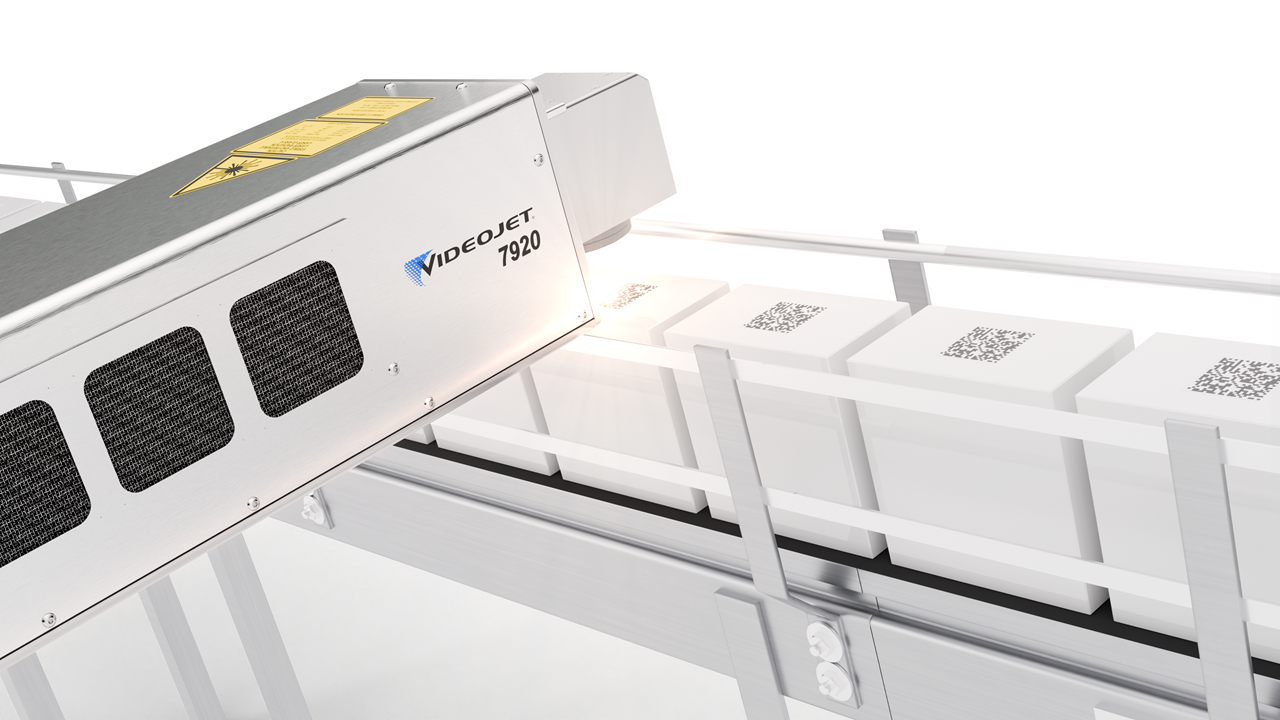

Introducing the Videojet 7920 UV laser marking system, a solution designed not just to mark products, but to transform how manufacturers seamlessly connect, monitor, and optimize their operations. With its advanced connectivity features, the 7920 addresses pain points head-on, offering a smarter, more agile approach to industrial marking. It is designed to help manufacturers streamline operations, improve traceability, and minimize IT overhead with ease.

Stay ahead with real-time updates on the latest news:

Smarter integration for smarter production

The Videojet 7920 is designed with plug-and-play integration in mind. Its compact footprint and flexible beam turning units allow for easy installation even in space-constrained production lines. But what truly sets it apart is its robust connectivity suite, which includes:

- Wi-Fi integration and cellular connectivity: Enables remote access and control, reducing the need for on-site IT intervention.

- EtherNet/IPTM, ProfiNet®, and serial interfaces: compatibility with a wide range of industrial automation systems.

- Videojet Remote Service: A cloud-enabled platform offering proactive diagnostics, software updates, and maintenance alerts.

These features allow manufacturers to monitor, manage, and maintain their laser marking systems from virtually anywhere, minimizing unplanned downtime and maximizing uptime.

Enhanced uptime with VideojetConnect™ Remote Service

A standout feature of the 7920 is its predictive maintenance capability, powered by real-time diagnostics through optional VideojetConnect™ Remote Service (VRS). This cloud-enabled platform provides:

- Continuous real-time system monitoring

- Proactive maintenance alerts to prevent issues before they occur

- Remote software updates

- Expert support from Videojet technicians

By leveraging VRS, manufacturers can reduce service response times, avoid costly production interruptions, and extend the life of their equipment.

Secure and scalable connectivity

Security is paramount in connected manufacturing environments. The 7920 supports secure communication protocols and user authentication, ensuring that only authorized personnel can access system settings and data. This is especially important for industries with strict regulatory standards, including pharmaceuticals, as well as the food and beverage sectors.

Moreover, the system’s connectivity is scalable, making it ideal for both single-line operations and large-scale, multi-line facilities. Whether you’re integrating with a Manufacturing Execution System (MES) or a cloud-based analytics platform, the 7920 is built to adapt.

Technical specifications: Connectivity overview

Below is a summary of the 7920’s connectivity features:

| Feature | Specification |

|---|---|

| Wi-Fi connectivity | IEEE 802.11 a/b/g/n, WPA2 encryption, remote access via secure web interface |

| Cellular connectivity | 4G LTE module (optional), remote diagnostics and control through VRS |

| EtherNet/IPTM | Industrial protocol support for PLC integration |

| ProfiNet® | Real-time industrial Ethernet protocol for automation integration |

| Serial communication | RS-232/RS-485 support for legacy system compatibility |

| USB ports | 2x USB 2.0 for data transfer and firmware updates |

| VideojetConnect™ Remote Service (VRS) | Cloud-based diagnostics, predictive maintenance, and software updates |

| Security protocols | Role-based access control, encrypted communication channels |

| Integration support | Compatible with MES, SCADA, and ERP systems |

Real-World impact

Videojet 7920 can help minimize downtime, improve code consistency, and achieve faster changeovers, keeping production lines moving. The system’s connectivity options not only simplify integration but also provide the tools needed to optimize production efficiency and support compliance with industry standards.

Conclusion

The Videojet 7920 UV Laser Marking System is more than just a high-performance marking solution; it’s a connectivity powerhouse. With its advanced integration capabilities, secure remote access, and proactive service features, the 7920 empowers manufacturers to stay ahead in an increasingly connected industrial landscape.

Ready to unlock new levels of efficiency and productivity on your production floor? Discover how the Videojet 7920 can transform your operations. Contact us today for a personalized demo or to learn more about its game-changing features.