From ultra‑processed to ultra‑functional: how fibre‑forward innovation is redefining real food in 2026

Videojet Knowledge Hub Team

ultra‑processed foods, fibre, clean-label, UPFs, fibremaxxing

Fibre-forward innovation is accelerating in 2026 as consumers look for “real food” with simpler ingredients and more functional benefits, and many are trying to reduce ultra‑processed foods (UPFs). This shift affects packaging teams first: more recipe reformulations, more label changes, and more SKU variation. The result is a higher bar for clear, compliant coding and marking, plus verification to reduce errors during changeovers.

Why fibre is rising as UPFs fall in 2026

Across consumer and industry trend forecasts, fibre has moved from a “nice to have” to a headline nutrient, often tied to gut health, satiety, and a preference for foods that feel less processed.1 The continued rise of “fibremaxxing” a social and wellness trend encouraging consumers to intentionally increase their daily fibre intake also reflects this shift, with growing interest in legumes, whole grains, and other naturally fibre‑rich ingredients.

At the same time, public and media attention on ultra‑processed foods continues to build, with more consumers actively questioning additives, long ingredient lists, and heavily engineered substitutes.2

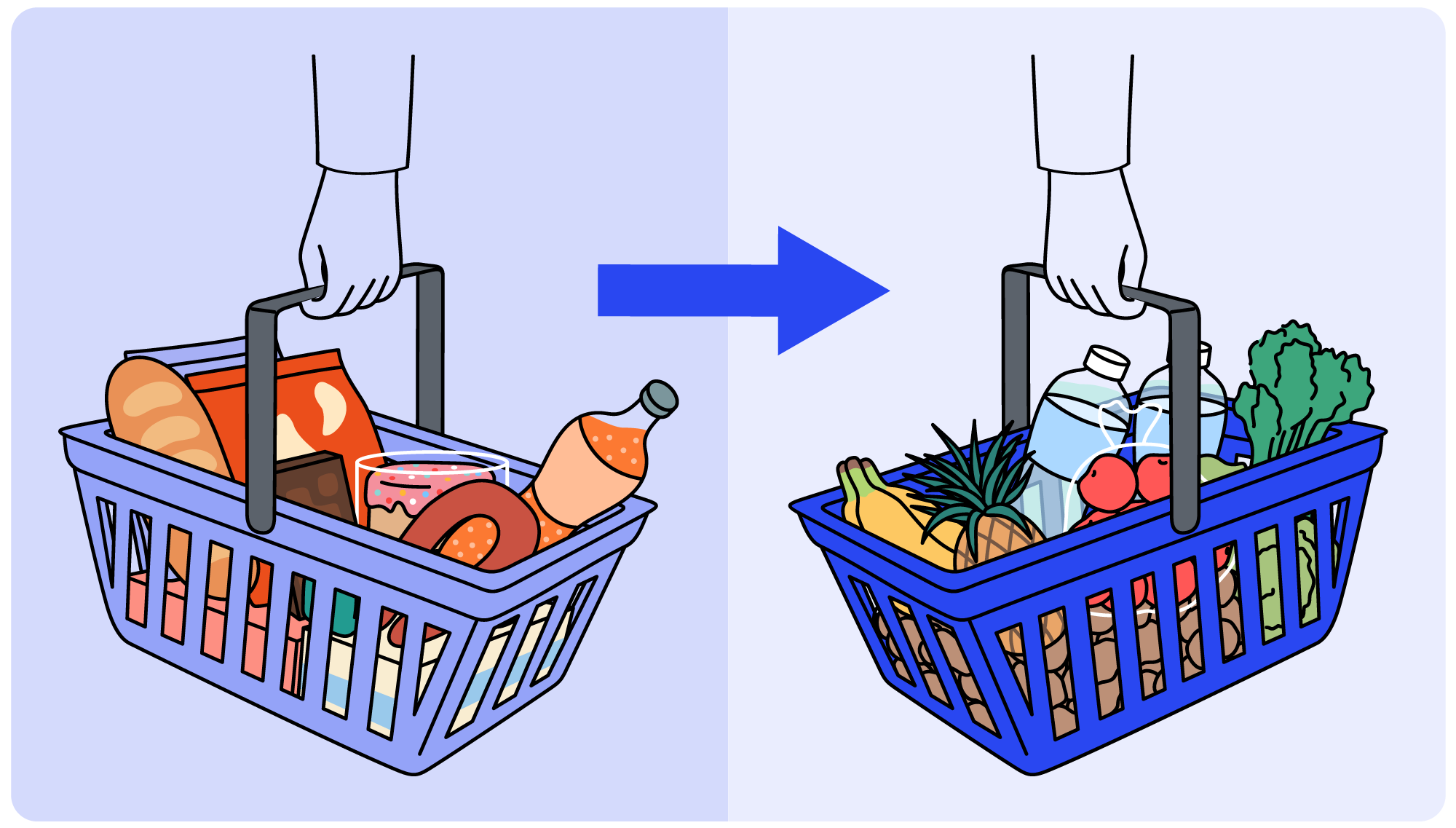

For manufacturers, that combination creates a predictable pattern:

What fibre-forward products change on packaging and labels

fibre-forward innovation shows up in several ways: adding legumes and whole grains, introducing fibre-enhanced product lines, and updating claims or front-of-pack messaging. Trend forecasts point to more fibre-focused products and messaging in 2026, which can cascade into frequent label updates. This shift also increases demand for clean label packaging and clearer ingredient transparency, as brands adapt their labeling to meet modern consumer expectations.

Simplicity is also moving to the front of pack. In the UK, M&S has introduced reduced‑ingredient front labels in its Only… Ingredients range, placing the minimal ingredient count where shoppers see it first. This is a visible retail‑level response to concerns about ultra‑processed foods and a signal that clear, consumer‑friendly ingredient cues can coexist with clean, legible variable data requirements on the same pack.6

From a packaging perspective, three areas tend to change most:

1) Ingredient lists and claim language

When recipes change, ingredient statements and claims often change too. Even small adjustments can trigger artwork revisions and new variable data rules, for example, different best-before windows, batch/lot logic, or language variants by market.

2) Allergen statements and cross-contact messaging

As brands reformulate, allergen declarations may need to be updated. This increases the importance of accurate coding workflows and verification during changeovers, especially when multiple SKUs run on the same line. These updates also reinforce the need to meet allergen labeling requirements and food labeling compliance standards across all markets.

3) Packaging formats and materials

Fibre-forward lines often expand into new pack types (smaller portions, multi-packs, premium “better-for-you” ranges). In parallel, brands may test different materials or finishes as they refresh the look and feel of “real food” positioning. That creates new coding and adhesion requirements across substrates.

Where coding and marking requirements get harder

When “real food” becomes the marketing promise, the on-pack information has to support it. That means codes need to be:

- legible: high contrast, consistent quality, readable at speed

- correct: right product, right language, right date/lot

- durable: survive handling, condensation, cold chain, abrasion

- efficient to manage: rapid changeovers, fewer operator touches

Common friction points packaging teams report in these cycles:

- short changeover windows that increase the risk of human error

- small print areas on premium designs or single-serve packs

- texts with the same content have different lengths in different languages

- multiple substrates (films, cartons, labels, caps) in one product family

- rework and scrap caused by incorrect date/lot printing

In short: Fibre-forward innovation increases food packaging variability. To keep pace, manufacturers typically standardize message templates, select coding technology by substrate and durability needs, and add verification to reduce changeover errors.

Which coding technologies are best suited for fibre-forward packaging?

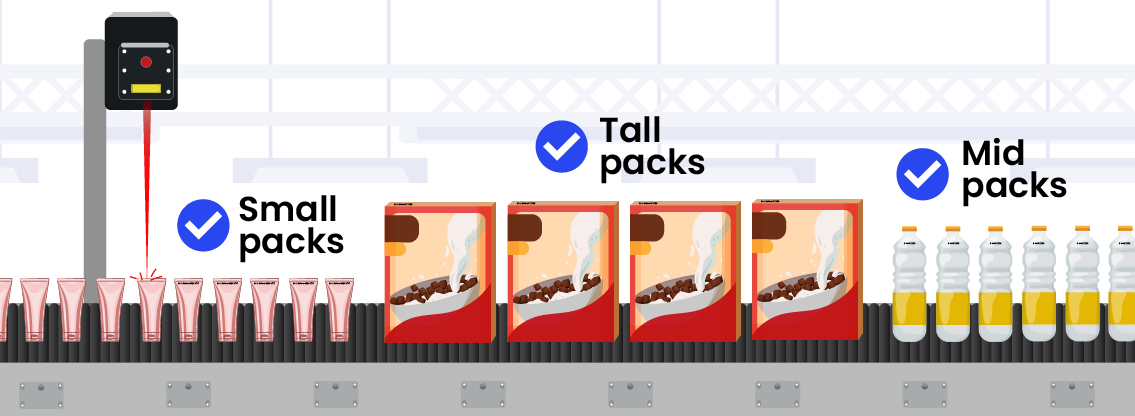

The right choice depends on substrate, line speed, required permanence, and the visual design constraints of the pack. Technologies commonly used include CIJ, TTO, and laser, often combined across different lines or packaging formats.

Decision table: CIJ vs laser vs TTO for fibre-forward packaging

| Technology | Best suited for | Typical uses | Key considerations |

|---|---|---|---|

| CIJ (continuous inkjet) | High-speed lines and varied substrates | Bottles, cans, films, some cartons | Ink selection for contrast/adhesion; environmental conditions |

| Laser marking | Permanent, ink-free marks aligned with premium design | Cartons, glass, some plastics/foils | Material compatibility, line integration, fume extraction |

| TTO (thermal transfer) | Crisp codes on flexible packaging | Pouches, flow-wrap, sachets, labels | Ribbon selection, print area planning, integration |

If you run multiple pack formats for one fibre-forward range, it’s common to use CIJ for containers, TTO for flexible films, and laser where permanence and design integration are priorities. These technology choices also support packaging traceability solutions that help manufacturers maintain accuracy, quality, and compliance throughout the supply chain.

Where Videojet fits in a practical workflow

Videojet helps manufacturers operationalize transparency with a system approach:

- print quality and legibility tuned to the substrate and line conditions

- message management to reduce manual entry during frequent SKU switches

- verification options to help catch wrong codes before product leaves the line

- service and support to maintain uptime when product portfolios expand.

With Videojet SmartFocus™ technology, the laser automatically adjusts the focus distance to a distance predetermined during setup, accommodating different product sizes and substrates quickly and accurately. This time-saving feature helps ensure that production can proceed swiftly and seamlessly without compromising on quality, especially valuable on lines with frequent changeovers and varied clean‑label or fibre‑forward packaging formats.

“I just set the appropriate height once on the display, and then it adjusts automatically and always fits. The most important thing is the legibility of the text. It’s a definite improvement because with Smart Focus, it’s like a recipe; it’s independent of the bottle size, and the laser more or less takes over the work.”

Checklist: Top 5 ways to adapt to fibre-forward packaging in 2026

- Map recipe changes to coding rules

Align reformulations with updated best-before logic, lot structure, and market-specific language needs. - Standardize templates for variable data

Use locked fields and controlled dropdowns where possible to reduce manual entry. - Test coding on every substrate in the range

Validate adhesion and contrast on films, cartons, labels, and closures before launch. - Design for code placement early

Ensure code areas are protected from seams, creases, and heavy graphics to improve readability. - Add verification where changeover risk is highest

Target lines with many SKUs, short changeover windows, or small print areas.

Conclusion

Fibre-forward innovation can be a growth opportunity, but it often increases packaging complexity behind the scenes. Clear, compliant coding and marking helps protect consumer trust and reduces rework risk when portfolios expand. If you are updating formulations or launching new “real food” ranges in 2026, Videojet can help you assess substrates, select the right coding approach, and strengthen changeover controls.

Maintain clear, compliant coding and marking across every SKU.

Contact Us:

FAQs

Ultra‑processed foods (UPFs) are industrially formulated products made mostly from refined or extracted ingredients, additives, and substances not typically used in home cooking. They often contain flavorings, colorings, emulsifiers, and other functional additives to enhance taste, texture, and shelf life. These products are usually energy-dense, low in fibre, and associated with higher risks of diet‑related chronic diseases.7

Not always. Many “simpler” products still require detailed allergen declarations, nutrition panels, and traceability information. The goal is clarity, not fewer compliance elements.

Standardized templates, controlled message selection, and automated verification steps can reduce the chance of wrong codes, especially when many SKUs share one line. Additionally, with Videojet SmartFocus™ technology, the laser automatically adjusts the focus distance to a distance predetermined during setup, accommodating different product sizes and substrates quickly and accurately, further minimizing errors during frequent changeovers.

As clean‑label and fibre‑forward products expand globally, brands often need to meet region‑specific requirements such as EU food labeling regulations, UK clean label compliance, the German Printing Ink Ordinance (GIO), and US FDA labeling requirements. These regulatory frameworks influence how ingredient lists, allergens, and date/lot codes appear on pack, and they highlight the need for global packaging standards and regional coding solutions for the food industry to ensure accuracy and consistency across markets.

TTO is typically used when brands need crisp, high-contrast codes on flexible films, while CIJ can also be used depending on the line and material. Depending on the film type, CO2, fibre, and ultraviolet (UV) lasers can all mark on flexible packaging material. However, UV lasers like the Videojet 7920 stand out for their ability to mark in small areas on a diverse range of materials. The best fit depends on substrate, speed, and durability requirements.

Sources

1 EatingWell’s Top 10 Food & Nutrition Trends for 2026

4 Global clean label trends. Nearly 1 in 2 consumers globally

5 The food and beverage trends to watch in 2026

7New US dietary guidelines recommend more protein and whole milk, less ultraprocessed foods