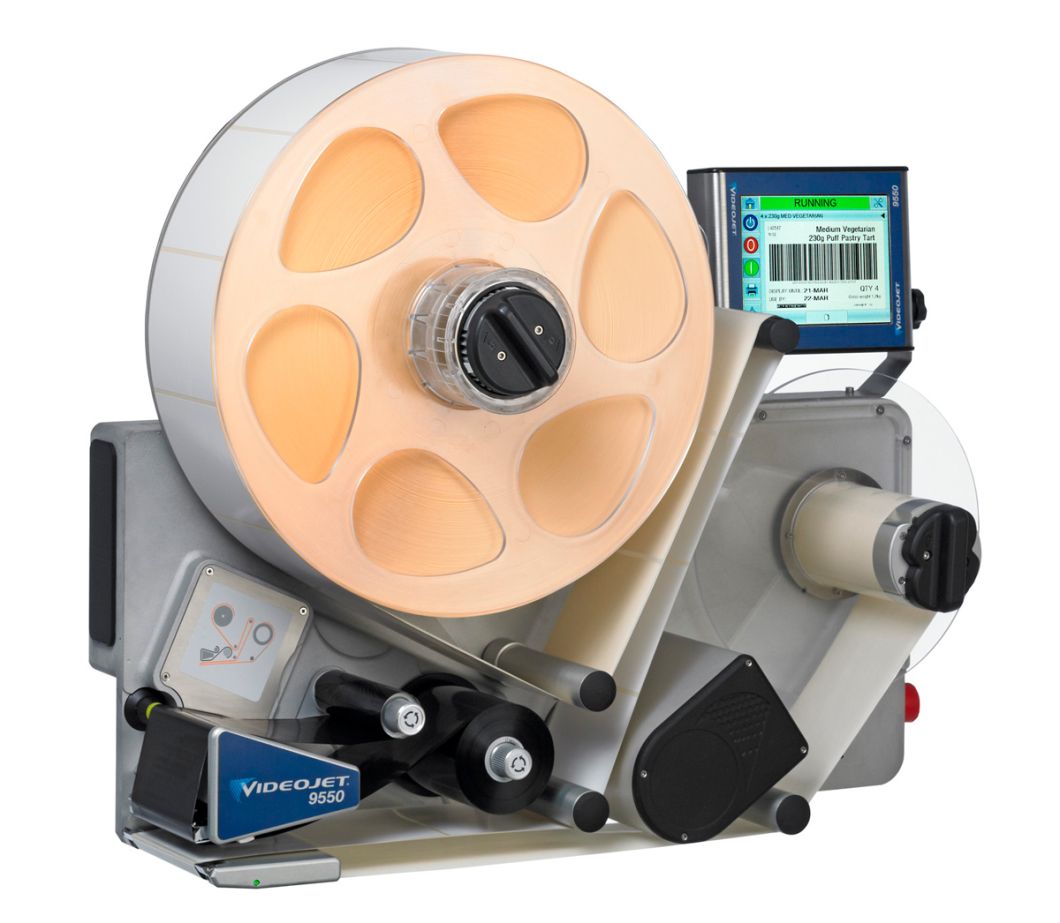

Videojet 9550 Label Print & Apply System (LPA)

The Videojet 9550 print and apply labeling machine (LPA) is no longer available for sale, but we invite you to explore our next-generation model, the Videojet 9560. Designed with improved performance and the latest features, it’s the perfect upgrade for your printing needs.

If you are looking for support on your existing Videojet 9550 LPA, we will continue to provide the required supplies and ensure most spare parts remain available for your convenience.

Ready to transition to the latest technology? Check out our Videojet 9560 print and apply labeling machine here, and contact us if you would like to discuss your options.

Support for customers with an installed Videojet 9550.

- Download the 9550 operator manual

- Download the 9550 spec sheet

- Get technical support

- Get service support

- Find a replacement printer

For more information, please contact your Videojet Sales Engineer.