One of the most common questions we hear from brands preparing for Sunrise 2027 is: “Do I need to print these codes in-line or can I pre-print them like I do today?” The answer depends on the type of data you want to include in the code – and making the right choice is critical for compliance, efficiency, and flexibility.

What is Sunrise 2027?

The existing EAN/UPC barcode has been hugely successful for over 50 years, but it has limitations since the data encoded is limited to the product’s Global Trade Item Number (GTIN).

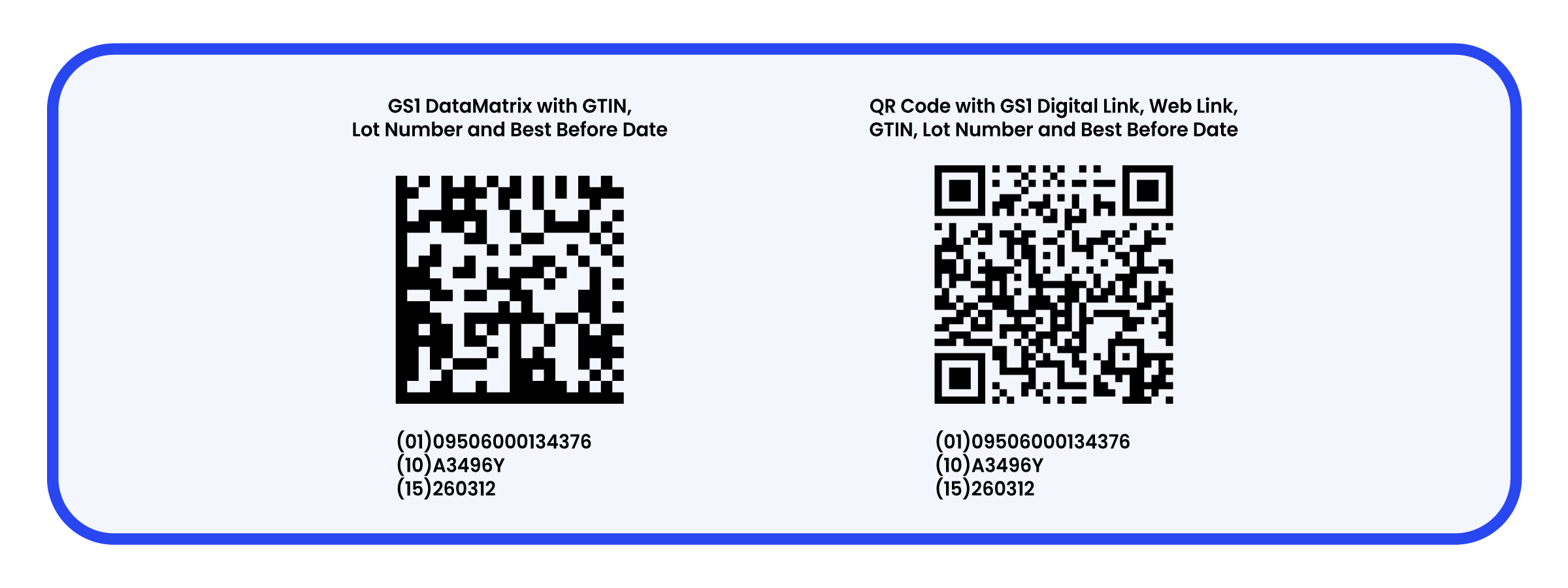

The Sunrise 2027 program enables brands to utilize GS1 DataMatrix and QR codes on their products, allowing for the encoding of additional data, including date and batch/lot codes, serialization, and links to online information. The codes can be scanned at checkout and also by customers for enhanced consumer engagement. You can read more about the initiative here: Videojet Sunrise 2027.

GS1 doesn’t dictate which data elements should be encoded in the 2D codes. This depends mainly on the nature of the product, industry norms, and the brand’s wishes.

Pre-printing 2D codes

If the data in your 2D codes is static (i.e., it doesn’t contain any variable information, such as dates or batch numbers), you can have your codes pre-printed on your labels or packaging material.

Suppose a serial number needs to be included in the code data. In that case, your packaging supplier can still pre-print the codes for you, provided they have a suitable digital or hybrid press capable of handling sequentially printed codes.

2D codes suitable for pre-printing

Advantages of using pre-printed 2D codes:

- No changes are needed to existing coding equipment

- Work with your current process and packaging line

- Your packaging supplier provides you with 2D codes that are verified for accuracy and quality

Printing 2D codes on the packaging line

Many brands will use 2D codes that include lot/batch and date-dependent variable information, so they will likely need to be printed onto the package or label as part of the packaging process. This moves the printing and quality responsibility from your label or packaging supplier to your packaging team.

2D codes that require in-line printing

While most packaging lines have equipment in place for date and batch coding, adding 2D codes to every package on the line is a significant change that brings some important benefits:

Advantages of printing 2D codes in-line with variable data

- Allows the encoding of live production data, such as date and lot codes, and serialization

- Reduces waste from packaging obsolescence

- Enables late-stage customization and lean manufacturing

- Supports future regulatory and retailer-driven data requirements

Why choose variable printing if it’s not mandatory?

While Sunrise 2027 does not currently require variable data, many brands choose to include it to:

- Meet internal traceability and quality goals

- Prepare for future regulations from industry or customers

- Enable faster response to recalls and quality issues

- Warn when a customer is purchasing an expired or recalled product

- Support customer-facing features like digital links and authentication

Steps to successfully implement in-line 2D code printing

Train your team

Ensure that your packaging team understands GS1 formatting, quality standards, verification methods, and that they are familiar with the GS1 Implementation Guide.

Review your coding equipment

Chances are, your current coding equipment already supports 2D code printing. However, it’s worth consulting with an expert to evaluate whether an upgrade is necessary. Modern coding solutions are designed to produce high-quality 2D codes and other variable data to support product traceability, regulatory compliance, and enhanced readability across the supply chain.

Common coding technologies include:

- Continuous inkjet (CIJ): non-contact printing at a range of speeds. Testing needed to ensure 2D codes are scannable

- Thermal inkjet (TIJ): high-resolution printing and simple operation

- Thermal transfer overprinters (TTO): high-resolution printing on flexible film and labels

- Laser marking systems: high-quality, permanent marking without fluids, ribbons or cartridges

Manage your print data

Efficient management of variable print data is essential for reducing errors and minimizing downtime during product changeovers. Solutions like Videojet CLARiSUITE® can centralize and streamline the control of print content across your production line. By consolidating data management for various coding technologies, these tools help improve accuracy and operational efficiency.

Invest in barcode verification tools

Codes must be readable from production through retail checkout. Use in-line or desktop verifiers to check for GS1 and ISO compliance.

Test and validate

Rigorously test your setup to ensure consistent print quality at production speeds before going live.

Final thoughts

While pre-printing on your packaging is the simplest way to add 2D codes to your products, this approach is only suitable for static data, such as the product GTIN (and possibly serial numbers).

Many brands will want to unlock the full potential of the 2D codes by encoding variable data like lot/batch and date codes. This will require the codes to be printed as part of your packaging operation.

With deep expertise in both static and variable data applications and the most comprehensive portfolio of coding solutions, Videojet is here to guide you every step of the way.

Additional resources

Videojet: Sunrise 2027: The Transition Period

Videojet: Success with GS1 2D Codes and Sunrise 2027 Compliance

Videojet: 2D Code Revolution

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Stay ahead with real-time updates on the latest news: